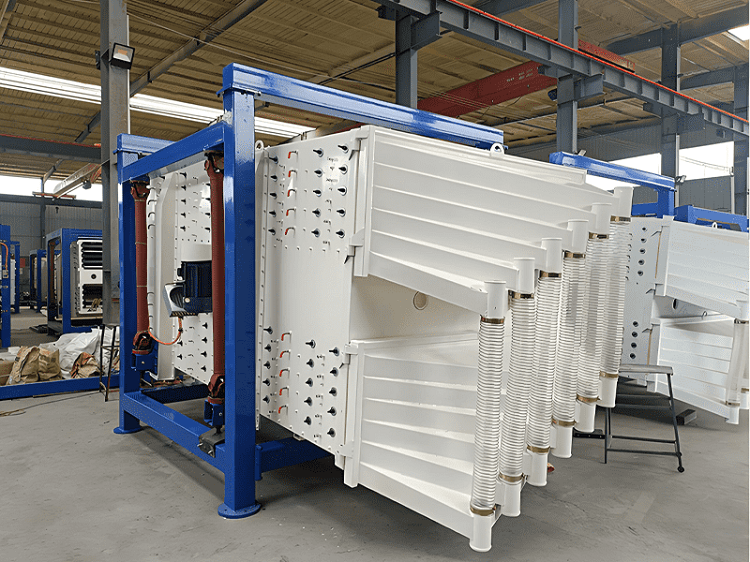

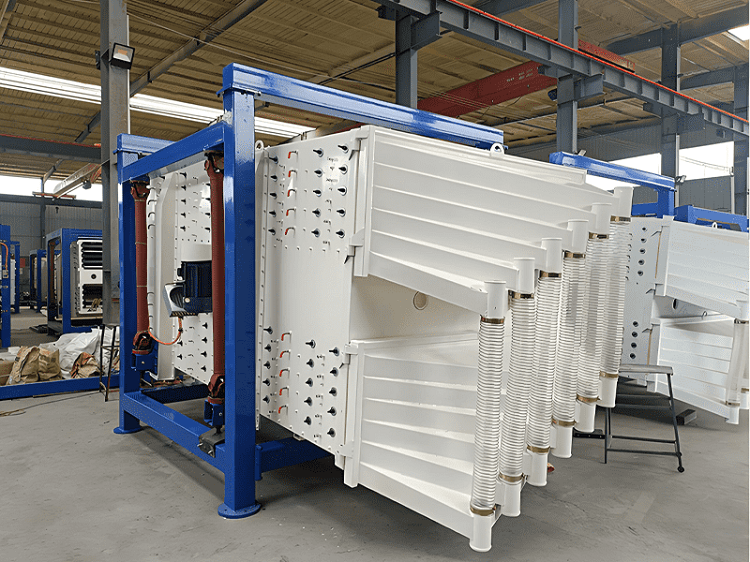

Overview of square swing sieve

Square Rocking Sieve (also known as reciprocating vibrating screen, precision vibrating screen ) is a kind of high-precision and high-efficiency screening equipment which combines the compound motion of vibration and rocking. It realizes the precise classification of granules, powder and slurry materials by simulating the traditional manual screening action - i.e. gentle reciprocating and swinging motion.

Its core features are high screening precision, large capacity, without destroying the particle structure of the material, widely used in chemical industry, metallurgy, non-ferrous metals, food, abrasives and other industries that require high screening efficiency and precision.

Technical characteristics of square swing sieve

-

High precision and high output: the unique swinging motion makes the material on the screen surface fully dispersed and close to the screen holes, which significantly improves the screening efficiency and precision.

-

Stable operation and long service life: reasonable design, sturdy structure, soft movement, small impact on the equipment foundation and materials, smooth and reliable operation and long service life.

-

Energy saving and environmental protection: low power consumption, low noise, less dust leakage, in line with the requirements of environmentally friendly production.

-

Unique mesh frame and mesh cleaning device: special mesh frame design and mesh cleaning system such as bouncing ball can effectively prevent the screen from clogging, prolong the service life of the screen, and maintain high productivity and high precision.

-

Modularized design, strong flexibility: single layer and multi-layer (up to 5 layers) can be chosen at will, and the discharge port can be rotated and adjusted by 360°, which is easy to arrange and connect with the assembly line.

-

Easy maintenance and low cost: adopting standardized and professional production of vibrating screen accessories, easy to replace, safe and reliable operation, saving maintenance cost.

-

Wide applicability: it can effectively screen materials in various forms such as granule, powder and slurry.

Working principle of square swing screen

The working principle of square swing sieve is essentially driven by the motor eccentric wheel structure, which produces a reciprocating inertia force around the fixed axis.

After the equipment is started, this inertia force makes the screen box (shaking body) produce a cradle-like back and forth reciprocating shaking. The sieve surface and the sieve box as a whole for the periodic swing, driving the material on the sieve surface to produce directional, jumping movement.

In this process:

-

Smaller than the sieve hole particles have more opportunities to pass through the sieve hole, become the sieve material.

-

The material larger than the sieve holes in the continuous tumbling and jumping, along the screen surface to move forward, and finally discharged from the discharge port, become the upper material.

The screen surface is usually arranged horizontally or slightly inclined ( 0°-5° ), and the inclination angle can be adjusted to adapt to different material characteristics.

The main technical parameter table of square shaking sieve

| Model |

Effective screening area (m²) |

Power (kw) |

Inclination angle of screen surface (°) |

Number of layers |

Rotation frequency (r/min) |

Stroke of screen box (mm) |

| WELL-1030 |

3 |

3 |

5-8 |

1-5 |

180-260 |

25-60 |

| WELL-1036 |

3.6 |

3 |

5-8 |

1-5 |

180-260 |

25-60 |

| WELL-1230 |

3.6 |

4 |

5-8 |

1-5 |

180-260 |

25-60 |

| WELL -1236 |

4.32 |

4 |

5-8 |

1-5 |

180-260 |

25-60 |

| WELL-1530 |

4.5 |

5.5 |

5-8 |

1-5 |

180-260 |

25-60 |

| WELL-1536 |

5.4 |

5.5 |

5-8 |

1-5 |

180-260 |

25-60 |

| WELL-1830 |

5.4 |

7.5 |

5-8 |

1-5 |

180-260 |

25-60 |

| WELL -1836 |

6.48 |

7.5 |

5-8 |

1-5 |

180-260 |

25-60 |

| WELL-2030 |

6 |

7.5 |

5-8 |

1-5 |

180-260 |

25-60 |

| WELL-2036 |

7.2 |

7.5 |

5-8 |

1-5 |

180-260 |

25-60 |

Note: WELL-2036 is the model with the largest effective screening area in the list. The screen surface inclination angle, rotary frequency and screen box stroke are all adjustable parameters, which can be optimized according to the material characteristics to achieve the best screening effect.