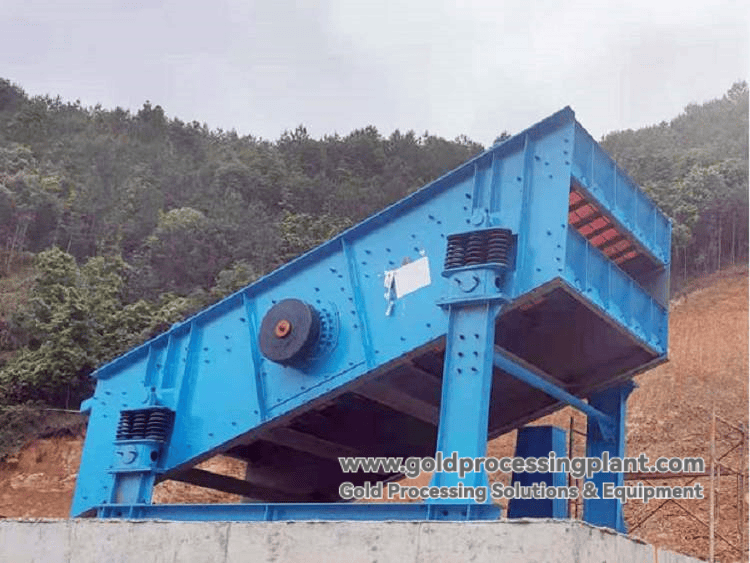

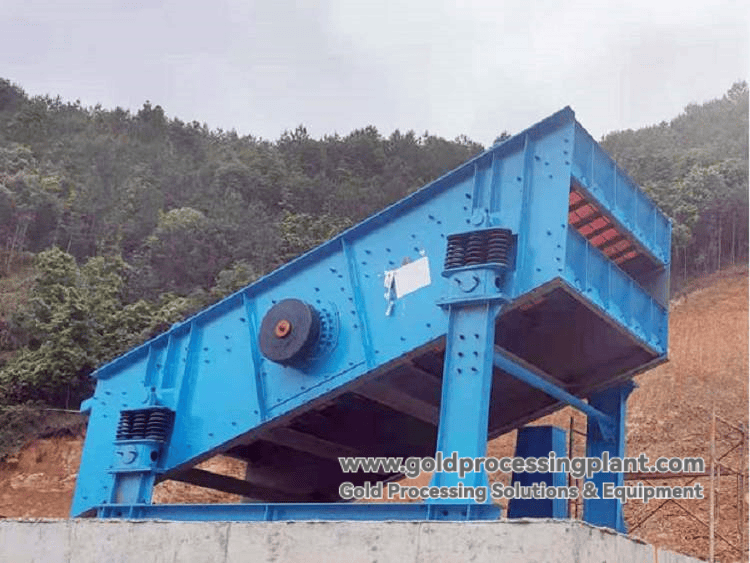

Product Overview

ZKB series linear vibrating screen is an efficient and universal new type of screening equipment, which adopts double motor synchronous drive technology to produce strong linear vibration force. The materials are evenly thrown up on the screen surface and move forward in a straight line, so as to realize rapid classification and screening. This equipment is especially suitable for processing powdery, granular and other dry materials, widely used in chemical industry, plastics, medicine, building materials, grain, carbon, fertilizer and many other industries, is the ideal choice to achieve high efficiency screening in the automated assembly line.

Applicable material characteristics:

-

Material particle size: 0.074 - 5mm (maximum feed size ≤100mm)

-

Material moisture content: < 70% of non-sticky dry materials

-

Application Scenario: Mainly used for dry screening, debinding and grading.

Core Advantages and Features

-

⚡ Strong and efficient excitation force: the use of dual motor drive and block eccentric exciter structure, the two motors synchronized reverse rotation, resulting in a strong combined force, the direction of the stable linear excitation force, high screening efficiency, large capacity.

-

🔧 Durable and easy maintenance:

-

No welding frame: the main parts of the screen box are connected by high strength bolts, which avoids deformation and cracking brought by welding stress, and the stability and life of the equipment are greatly improved.

-

Smooth soft drive: the tire coupling is used for soft connection, effectively cushioning the impact force, protecting the motor and shaker, and running more smoothly and reliably.

-

🔇 Airtight and low noise, environmental protection and energy saving:

-

Fully enclosed structure: effectively prevent dust from escaping, improve the working environment, meet the requirements of environmental protection, more suitable for automated assembly line operations.

-

Low energy consumption and low noise: the optimized design of the kinetic parameters, while ensuring high efficiency screening, low energy consumption and low noise operation.

-

🛡️ Long life and high reliability:

-

High screen tension, low wear and tear, long service life.

-

High screening precision, flexible control of product particle size by adjusting parameters such as inclination angle and amplitude.

-

📦 Smooth discharge: linear material movement trajectory ensures automatic and fast discharge without stagnation and clogging.

Technical parameters (example)

Note: The following is the range of parameters for common models, the specific model needs to be determined according to customer demand.

| Parameter |

Parameter range/description |

| Number of screen decks |

1-3 layers |

| Hole size |

0.074mm - 5mm (customizable) |

| Maximum feed size |

≤ 100mm |

| Capacity |

Depends on model, material characteristics and screen configuration, ranging from several tons to tens of tons per hour. |

| Power (Kw) |

Depending on the model size, usually equipped with dual motors, the total power ranges from 2×0.75kW to 2×7.5kW or higher. |

| Screen inclination |

Typically 0°-10° (adjustable) |

| Double amplitude |

8-10mm (adjustable) |

Applications and Scenarios

-

Plastic industry: plastic granules (new material, recycled material) screening, debris removal.

-

Chemical industry: resin, pigment, paint, rubber additives and other powder classification.

-

Pharmaceutical and foodstuffs industry: accurate screening of raw material medicine, traditional Chinese medicine powder, flour, starch, powdered sugar and table salt.

-

Building materials industry: grading of quartz sand, cement, abrasives (silicon carbide, emery).

-

Metallurgical minerals: grading of carbon, graphite powder, chemical fertilizer, compound fertilizer particles.

-

Grain processing: grain cleaning, grading and removing impurities.

Why choose our ZKB linear screen?

-

Designed for industry: heavy-duty structure, can adapt to continuous 24-hour high-intensity operation.

-

Extremely low maintenance cost: modular design, easy screen replacement; bearing housing and other key components are easy to overhaul.

-

Customized: We can provide the most suitable model configuration (such as the number of screen mesh layers, material, outlet direction, etc.) according to your specific material characteristics, output requirements and installation space.

-

Quality assurance: exquisite manufacturing process and strict quality inspection system, to ensure that each piece of equipment is stable performance, durable.