CIL process for gold mines: an efficient solution for gold extraction by simultaneous leaching and adsorption

The CIL process is an advanced gold extraction technology that combines cyanide leaching and activated carbon adsorption in the same tank. By optimizing the leaching kinetics and adsorption efficiency, the CIL process is particularly suitable for thedevelopment ofhigh-grade gold oresandgold ores containing associated silver and copper, and has the significant advantages of saving investment, high recovery rate and low production cost.

I. Core aspects of the CIL process for gold ores

-

Ore preparation system

-

Crushing section: adopting two-stage and one closed-circuit crushing process (jaw crusher + cone crusher), crushing the ore to -15mm.

-

Grinding and Classification: Ball mill and hydrocyclone form a closed-circuit system to control the grinding fineness to -200 mesh accounting for 90-95%, forming a slurry with a concentration of 40-45%.

-

Pre-leaching slurry adjustment system

-

pH adjustment: Add lime to adjust the pH value of the slurry to 10.5-11.5 to create the best cyanide conditions.

-

Sodium Cyanide Addition: Add sodium cyanide precisely in the front-end leaching tank and maintain the initial concentration at 0.03-0.05%.

-

Impurity removal treatment: Set up debris removal screen to remove wood chips and other impurities to protect the subsequent equipment.

-

Leaching adsorption system (CIL core)

-

Stepped leaching tank set: usually 8-10 tanks are arranged in series, with the first 2-3 units dedicated to cyanide leaching and the last 5-7 units synchronized for leaching and adsorption.

-

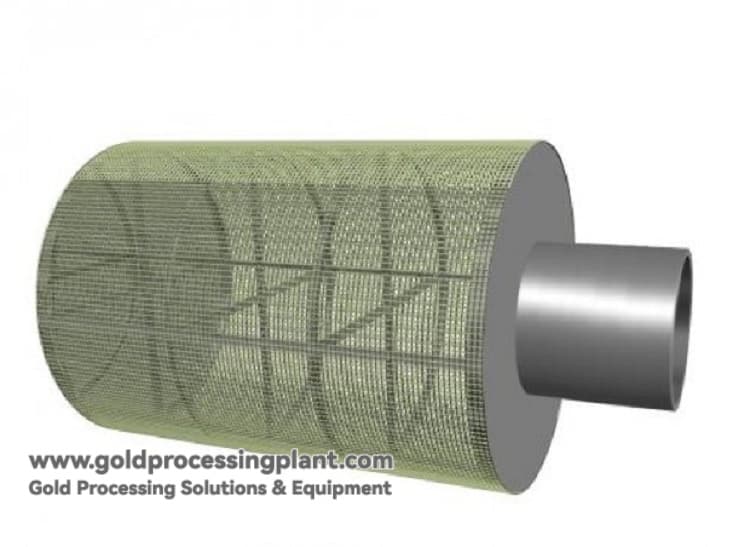

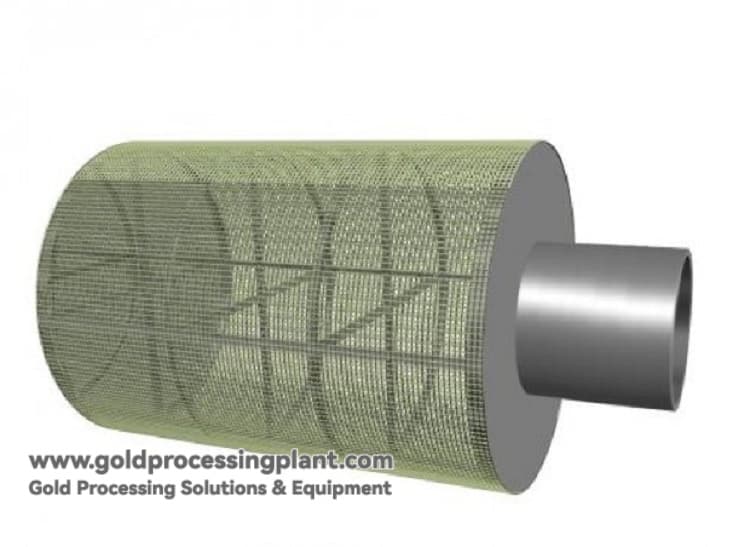

Activated carbon adsorption: 6-16 mesh coconut shell activated carbon is used, adopting counter-current moving method (fresh carbon is added from the last tank).

-

High-efficiency inflatable system: adopting central inflatable lifting tube technology, oxygen utilization rate is increased by 40% and energy consumption is reduced by 70%.

-

Carbon concentration control: maintain 10-25g/L carbon density to optimize adsorption efficiency.

-

Gold-carrying carbon treatment system

-

Desorption electrolysis: high temperature and high pressure desorption (150℃, 0.5MPa), using 1% NaOH+0.1% NaCN desorption solution, desorption time 2-6 hours, desorption rate>99%.

-

Carbon regeneration: after desorption, the poor carbon is acid washed by 3-5% hydrochloric acid, and then thermally regenerated in the rotary kiln at 700-750℃, with the activity recovery rate of >95%.

-

Precious liquid treatment: the precious liquid recovers gold and silver through the replacement of zinc powder or electrolytic deposition.

-

Smelting and refining system

-

Gold sludge treatment: collect cathode gold sludge, and remove impurities by acid washing.

-

Smelting and casting: Medium frequency smelting furnace (temperature 1200℃) refining, casting into gold ingot with purity above 99.9%.

Second, the advantages of gold CIL process technology

-

Significant economic benefits

-

Save 66% investment than traditional CCD process

-

Reduce capital backlog and accelerate turnover

-

Improve the recovery rate of associated metal (silver recovery rate 85-90%)

-

High efficiency and energy saving

-

Synchronized leaching and adsorption, shortening the process flow

-

70% energy saving in centralized filling system

-

High-temperature and high-pressure rapid desorption (50% shorter than traditional methods)

-

Environmental protection and safety

-

Closed system design reduces cyanide volatilization.

-

High recycling rate of activated carbon (loss <10g/t)

-

Wastewater treatment meets emission standards

-

Intelligent control

-

PLC/DCS automatic control system

-

Online monitoring of key parameters such as pH, CN-concentration, dissolved oxygen, etc.

-

Digital management system to realize remote monitoring

Applicable Ore Types

-

High-grade gold ore

-

Gold ore with associated metal

-

Gold-silver symbiotic ore (Ag:Au>5:1)

-

Copper-bearing gold ore (Cu<0.5%)

-

Lead-zinc-bearing gold ores

-

Special gold resources

-

Tailings Re-election Resources

-

Residual ore bodies from old mines

-

Pre-treated ore of difficult-to-treat gold ore

IV. Key Equipment Configuration

| System |

Core Equipment |

Technical Characteristics |

| Crushing System |

Hydraulic Cone Crusher |

Layer crushing, uniform product size |

| Grinding System |

Overflow ball mill |

Energy saving 30%, large capacity |

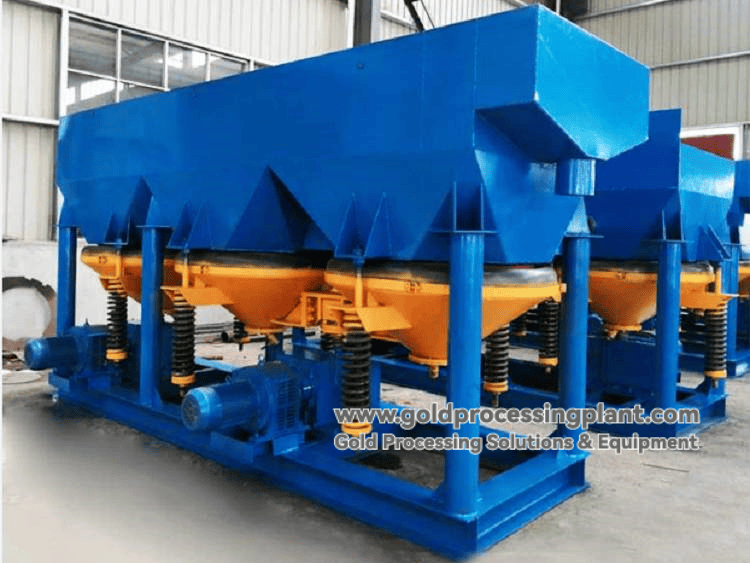

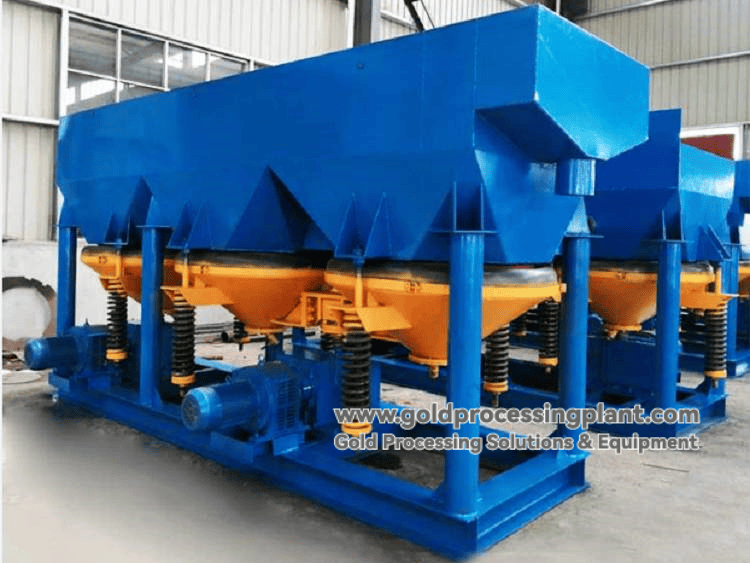

| Leaching System |

High efficiency cyanide leaching tank |

Centralized aeration, low energy consumption |

| Adsorption system |

Activated carbon adsorption tank |

Anti-corrosion design, high efficiency |

| Desorption system |

High pressure desorption column |

Fast desorption, automatic control |

| Electrolysis system |

Electrolysis tank set |

Efficient deposition, high grade gold mud |

V. Technical Service Support

-

Engineering Design

-

Production support

-

Environmental protection program

-

Cyanide wastewater treatment system

-

Comprehensive utilization of tailings

-

Environmental compliance consulting service

The gold CIL process realizes efficient and energy-saving gold production through the synchronization of leaching and adsorption. For detailed CIL process plan and equipment configuration, please contact our professional technical team, we will provide you with the most suitable CIL solution for gold mine.