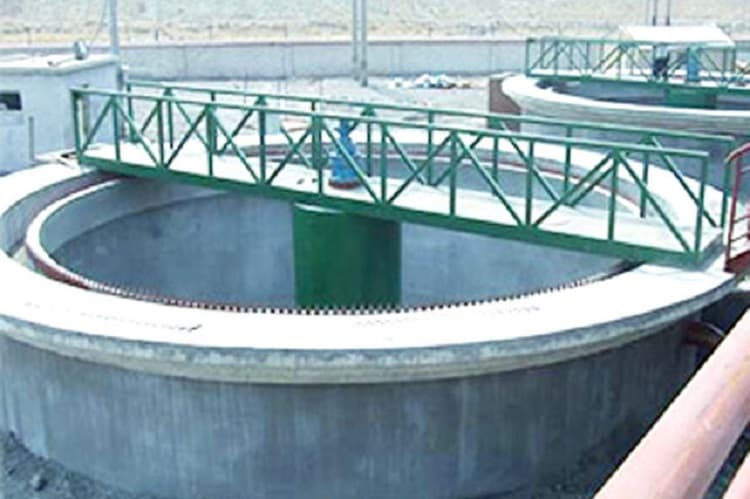

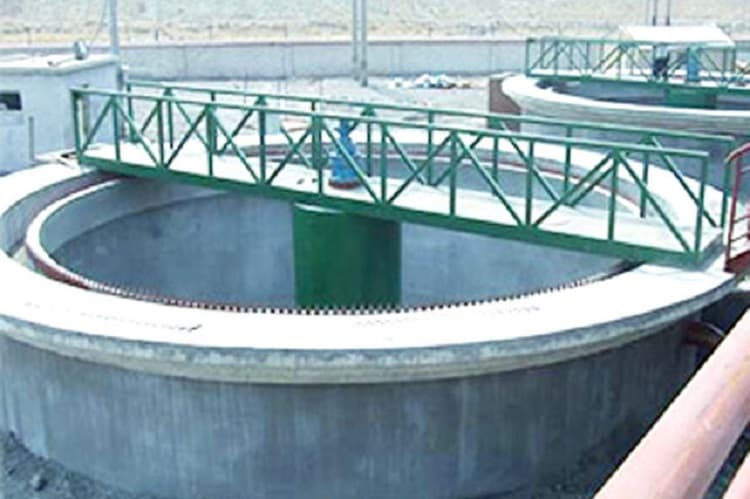

Overview of NZ(S) Type Center Drive Thickener

NZ(S) type (or TNZ type) center-driven thickener is a kind of high-efficiency, continuous working concentration and clarification equipment. It adopts center drive and automatic rake lifting technology, separates and concentrates the solid particles in the suspension through the principle of gravity settling, and obtains clarified overflow water at the same time.

This equipment is widely used in solid-liquid separation operation in mineral processing, coal, chemical industry, environmental protection and other industries for its large capacity, stable operation, easy maintenance and high degree of automation. It is an ideal solution for material dewatering, resource recovery and wastewater purification in modern industrial production.

NZ (S) type center drive thickener working principle

The slurry or sewage enters into the thickening pool uniformly from the feeding cylinder at the upper part of the pool body. Under the action of gravity, the solid particles begin to settle freely, and the coarser and heavier particles settle rapidly to the cone at the bottom of the pool.

The rake frame installed in the center of the thickener rotates slowly under the drive of the transmission device. The sludge (sand) settled to the bottom of the pool is gradually scraped by the rotating rake teeth to the center of the bottom of the pool discharge port, and finally discharged through the bottom flow pump, becoming the concentrated product. The clarified liquid after separation flows out from the tank body along the overflow weir of one week.

When encountering overloading or excessive sand sedimentation, the automatic rake lifting device will be activated to lift the rake frame in order to prevent rake pressure accidents and ensure the safe and continuous operation of the equipment.

Core Advantages and Features of NZ(S) Center Drive Thickener

| Structural Advantages |

Performance and control advantages |

| ✅ Center drive structure: direct power transmission, high torque, low energy consumption, smooth and reliable operation. |

✅ High-efficiency thickening: specially designed rake teeth can effectively collect sludge, prevent slatting, and improve the concentration of underflow. |

| ✅ Intelligent rake lifting system: ≤Φ12m model is equipped with manual rake lifting; >Φ12m model is equipped with electric rake lifting and integrated with overload automatic protection and alarm function, safe and worry-free. |

✅ Large treatment capacity: Optimized structural design ensures large settling area and treatment capacity. |

| ✅ Sturdy transmission system: adopts planetary gear reducer with strong carrying capacity, long service life and maintenance-free. |

✅ Stable operation: the equipment has low failure rate and can realize 24 hours continuous unattended operation. |

| ✅ Flexible configuration: full bridge or center column support structure, steel or concrete pool body optional, to meet a variety of working conditions and site requirements. |

✅ Easy operation and maintenance: high degree of automation, low daily maintenance workload. |

NZ (S) type center drive thickener main technical parameters table

| Specification Model |

Diameter of pool body (m) |

Sedimentation area (m²) |

Rake speed (r/min) |

Production capacity (t/d) |

Power of driving motor (kw) |

Equipment weight (kg) |

| NZ-1.8 |

1.8 |

2.55 |

0.5 |

1.3~5.6 |

1.1 |

1490 |

| NZ-3.6 |

3.6 |

10.2 |

0.4 |

5 to 24 |

1.1 |

2875 |

| NZ-6 |

6 |

28 |

0.3 |

14 to 62 |

3 |

8575 |

| NZ-9 |

9 |

63.5 |

0.26 |

32 to 150 |

3 |

5370 |

| NZ-12 |

12 |

113 |

0.19 |

≤250 |

3 |

8880 |

| NZ-15 |

15 |

176 |

0.113 |

≤390 |

5.5 |

10557 |

| NZ-18 |

18 |

254 |

0.1 |

≤552 |

5.5 |

12338 |

| NZ-24 |

24 |

452 |

0.1 |

200~1440 |

7.5 |

24500 |

Note: The production capacity varies according to the nature of materials (particle size, concentration, etc.), the table is a reference range. nz-6 and larger sizes are usually equipped with a more complete automatic control system.

Application Fields

-

Mineral processing industry:

-

Concentration of concentrates: dewatering of concentrates of copper, iron, gold, lead and zinc, etc., and sending them to filtration process after increasing the concentration.

-

Tailings treatment: Concentrate the tailings slurry, realize the efficient return water utilization, reduce the pressure of tailings storage.

-

Coal industry:

-

Environmental protection engineering:

Selection Guide

-

For small-scale plants/projects: NZ-6 to NZ-12 sizes are recommended.

-

Medium sized plants/projects: NZ-18 to NZ-24 sizes (motorized rake type) are recommended.

-

Large-scale plants/projects: NZ-30 and above are recommended.

-

Coal and Wastewater Treatment: NZ-12 or above is recommended, and can be equipped with automatic dosing system and inclined tube/inclined plate packing to further enhance efficiency. Concrete tanks are often used for wastewater treatment.

Service Support

-

Technical Consultation: Provide free process program design and equipment selection.

-

Installation guidance: professional engineers on-site guidance for installation and commissioning.

-

Spare parts supply: ensure the fast supply of original spare parts.

-

Modification and upgrading: Provide modernization and upgrading services for the old thickener.

Summarize

NZ(S) type center drive thickener is the main core equipment in the field of solid-liquid separation. Its mature technology, excellent reliability, flexible configuration and high degree of automation make it a key piece of equipment for efficient dewatering, resource recovery and clean production in a wide range of industries, from mineral processing to environmental protection. Choosing NZ(S) thickener means choosing stable, efficient and long-lasting operation guarantee.