Several main methods of gold ore beneficiation: gravity, flotation, cyanidation full analysis of the

Several main methods of gold ore beneficiation: gravity, flotation, cyanidation full analysis

In the development of gold resources, beneficiation is the core link to determine the recovery rate and economic benefits. In the face of a wide variety of gold ores, there is no "one-size-fits-all" process. Gravity separation, flotation and cyanidation, as three mainstream and mature gold ore beneficiation methods, have their own unique applications and advantages. Understanding their principles and applicability is the first step in selecting the best technology route to maximize resource value.

With more than 20 years of professional experience, GoldProcessingPlant is well versed in all mainstream beneficiation processes and can customize the most efficient and cost-effective combined solution according to your ore characteristics.

I.Gravity Concentration: Physical Separation and Classic Recovery of Coarse Gold

Gravity beneficiation is a physical method that utilizes the density difference between gold and vein minerals to achieve separation in fluid media. It is one of the oldest, most environmentally friendly and least expensive methods of gold separation.

-

Core principle: Specific gravity difference, "heavy sinking and light floating", high density gold particles sink and gather under the action of water flow, vibration or centrifugal force, thus separating from low density chondrites.

-

Main equipment:

-

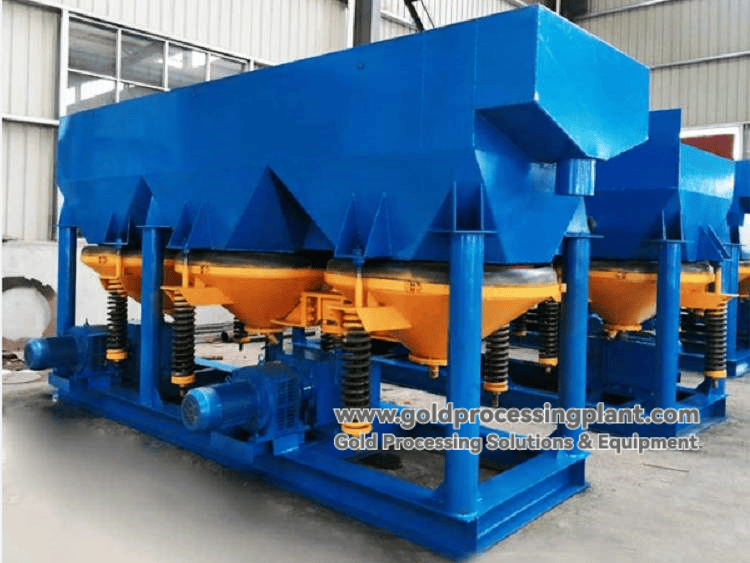

Jigger: large processing capacity, excellent recovery of coarse and medium-grained gold, often used as roughing equipment.

-

Shaking table: high sorting precision, used for coarse concentrate selection, can obtain high-grade gold concentrate.

-

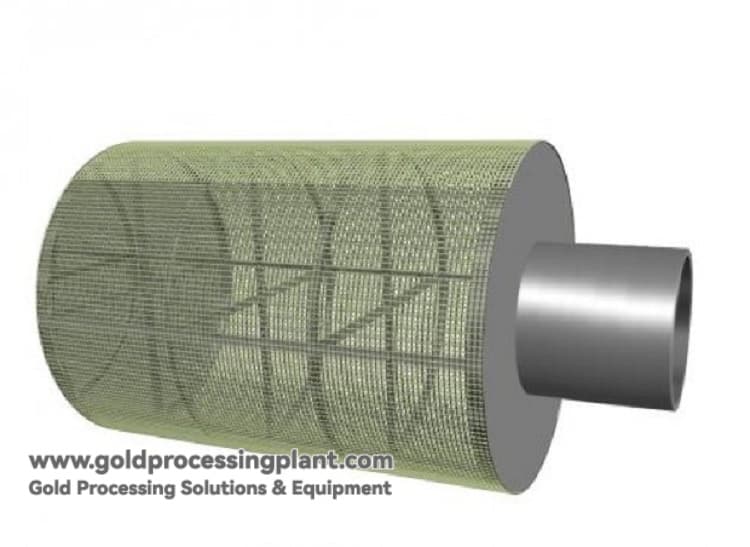

Centrifugal concent rator: utilizing centrifugal force field, it has very high recovery rate for fine-grained gold (-0.037mm), and is the core of modern gravity separation technology.

-

-

Advantageous features:

-

Low investment and operation cost, no chemical pollution.

-

Extremely high recovery rate (>95%) for coarse-grained free gold.

-

Simple process flow, short construction period.

-

-

Applicable ores:

-

Alluvial gold ore: the most important application area.

-

Rock gold ore: commonly used in the grinding circuit after the early recovery of dissociated coarse-grained gold, effectively preventing its over-crushing, is to improve the total recovery rate of the "tool".

-

-

Our professional services: we provide a full range of gravity separation equipment from jig, shaking table to Nelson centrifugal concentrator, and we are good at integrating them into the combined process to realize "early recovery and high recovery".

Second, flotation method: the chemical art of enriching gold in sulfide ore

Flotation is the most widely used method to deal with rock gold ore, especially gold-bearing sulfide ore. It is through the physicochemical principle, the gold selectively attached to the bubble and enriched to the foam product.

-

Core Principle: Utilizing the difference in physicochemical properties between gold and the surface of the vein minerals, the gold minerals are selectively hydrophobized and floated out on the bubbles by the addition of trapping agents, foaming agents and adjusting agents.

-

Typical Process: Crushing - Grinding - Flotation (Roughing, Sweeping, Concentration) - Concentrate Dewatering.

-

Advantageous Features:

-

High recovery rate, significant effect on the recovery of micro-fine grained leached gold.

-

Highly efficient enrichment of gold, which greatly increases the concentrate grade and reduces the subsequent smelting cost.

-

It can simultaneously recover valuable metals (e.g. copper, lead, zinc) that coexist with gold.

-

-

Applicable ores:

-

Gold-pyrite/toxic sand ore: the most typical flotation object.

-

Gold-bearing polymetallic sulfide ores.

-

Pre-enrichment of some difficult-to-process gold ores.

-

-

Our professional services: We have advanced flotation test platform and exclusive pharmaceutical formula, we can optimize the flotation process (such as stage grinding and floating) and pharmaceutical system for you, and provide KYF, XCF, SF series of high-efficiency flotation machine, to ensure that we can obtain the best sorting index.

Cyanidation: a modern tool for extracting dissociated gold

Cyanidation is a chemical method to dissolve gold in ore through oxygenated cyanide solution and then recover it from the solution, which is the cornerstone of modern gold industry. The main methods include carbon paste (CIP), carbon in leach (CIL) and heap leach.

-

Core Principle: Using sodium cyanide solution to react with gold under aerobic conditions to generate soluble gold-cyanide complexes, and then recovering gold from the solution through activated carbon adsorption or zinc powder replacement.

-

Main Processes:

-

Carbon Immersion Process (CIL): leaching and adsorption are carried out simultaneously in the same series of tanks, with short flow, low investment and high efficiency, which is the most mainstream cyanidation process at present.

-

Carbon Impoundment Process (CIP): Cyanide leaching is completed first, followed by carbon adsorption, applicable to specific ores.

-

Heap leaching method: build a heap of low-grade ore and leach it with cyanide solution spraying, with the lowest investment and cost, it is the ideal choice for treating low-grade oxidized ore.

-

-

Advantageous features:

-

Very high gold recovery, usually up to 90%-96%.

-

It has the best effect on the recovery of fine-grained and micro-fine-grained leach-like gold.

-

Mature technology, high degree of automation, stable operation.

-

-

Applicable ores:

-

Gold ores with high degree of oxidation.

-

Flotation gold concentrate.

-

Primary ores with fine-grained leaching distribution.

-

-

Our professional service: We are experts in CIP/CIL and heap leach process, and can provide a full set of core equipment and automation control system from leaching adsorption, desorption electrolysis to smelting and ingot casting, ensuring high recovery rate and low cyanide consumption.

How to choose? Process combination is the key!

In real projects, it is often difficult to achieve optimal results with a single process, and GoldProcessingPlant 's core strength lies in the flexibility to combine these processes based on the mineralogical results of the ore process to achieve a "1+1>2" result.

| Ore Type | Recommended Process Combination | Advantages |

|---|---|---|

| Quartz vein ores with coarse-grained gold | Gravity separation + flotation | Gravity separation recovers coarse-grained gold in a timely manner, while flotation captures fine-grained gold, maximizing the overall recovery rate. |

| Complex and difficult to process sulfide ores | Flotation + Cyanidation (CIL) | Enrichment of gold concentrate by flotation, and cyanidation of concentrate to reduce the cost of cyanidation and increase the recovery rate. |

| Low-grade oxidized ore | Gravity separation (pre-enrichment) + Heap leaching | Gravity Separation and Tail Throwing, increase the grade into the heap, greatly reduce the cost of heap leaching. |

Why choose GoldProcessingPlant?

-

Process mastery: We not only provide equipment, but also master the mechanism and application of all the core processes of gravity separation, flotation and cyanidation.

-

Customized Solutions: We reject "one size fits all" and customize each line based on your ore characteristics and investment objectives.

-

Combined Process Experts: We specialize in designing combined gravity-flotation-cyanidation processes to overcome complex and difficult gold ores, and achieve both improved recovery and economic efficiency for you.

Let GoldProcessingPlant's team of professionals diagnose the characteristics of your ore and select the best process path to maximize the value of each gram of gold!