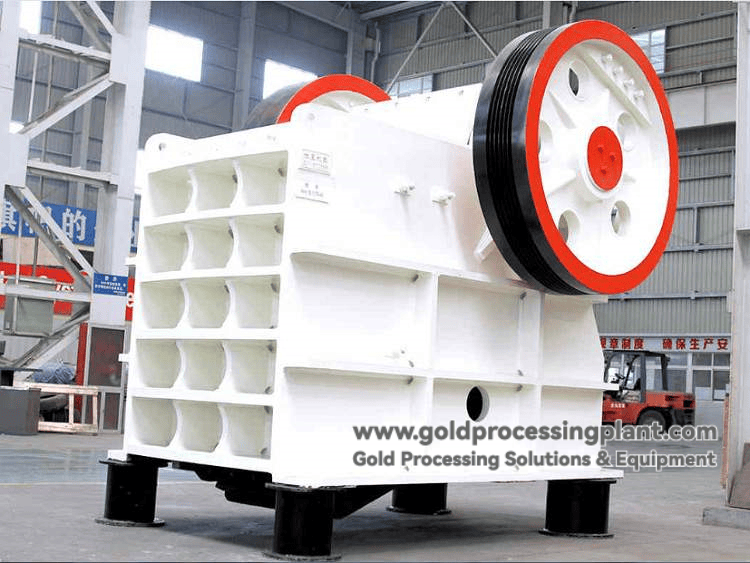

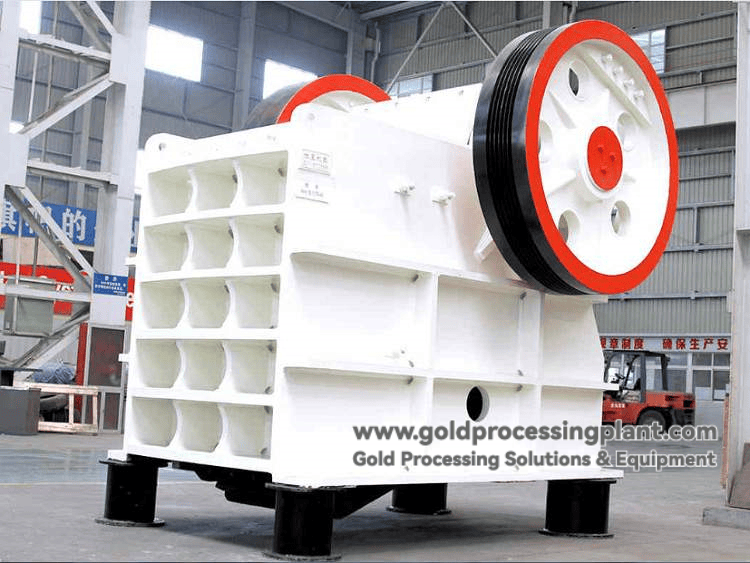

Jaw Crusher Overview

Jaw crusher, commonly known as "tiger mouth", is a kind of primary crushing equipment most widely used in mining, building materials, infrastructure and other fields. It is mainly used for coarse crushing and medium crushing of ores and materials of various hardness, and its compressive strength can reach up to 320 MPa.

With the remarkable features of large crushing ratio, even product size, simple structure, reliable operation and convenient maintenance, this equipment has become the indispensable first key equipment in the crushing production line, and it is widely used in many sectors such as mining, smelting, building materials, highway, railroad, water conservancy and chemical industry.

Working Principle of Jaw Crusher

The crushing chamber of Jaw Crusher is composed of fixed jaw plate and movable jaw plate (movable jaw), the movable jaw is driven by eccentric shaft to make periodic reciprocating swing, simulating the movement of animal's two jaws to realize crushing.

The working process is divided into two stages:

-

Crushing stroke: when the movable jaw plate is close to the fixed jaw plate, the material located between the two jaw plates is crushed by the combined effect of extrusion, splitting and bending.

-

Discharge stroke: when the movable jaw plate leaves the fixed jaw plate, the material that has been crushed to a size smaller than the discharge opening is automatically discharged from the discharge opening at the bottom of the equipment by its own gravity. At the same time, the large pieces of material to be crushed in the upper layer of the crushing chamber will fall down and prepare for the next crushing stroke.

This cyclic movement is repeated week after week, realizing continuous crushing operation.

Jaw Crusher Advantages and Features

-

Reliable structure and easy maintenance: Simple structure, easy operation, easy maintenance and replacement of parts, minimizing downtime for maintenance and ensuring the continuity of production.

-

Robust core components: the movable jaw plate is made of high-strength cast steel, and the core eccentric shaft is machined from forged billet and precision heat-treated, which ensures the extraordinary stability and load-bearing capacity of the host machine and long service life.

-

Excellent load-bearing capacity: The larger and more durable eccentric shaft bearings are designed to give it higher load-bearing performance and enable it to cope with high-intensity and high-load crushing tasks.

-

Wide applicability: Can handle almost any type of hard, abrasive ores and rocks, ideal for primary crushing.

-

Cost-effective: relatively low initial investment costs, economical operation and maintenance costs, and an excellent overall price/performance ratio.

As the "first gate" of ore crushing, the jaw crusher has established itself as the centerpiece of the crushing field with its unparalleled reliability, rugged construction and wide applicability. It is the cornerstone of any crushing line, and its performance directly determines the processing capacity and efficiency of the whole line. Whether it is a new construction project or the renovation of an old line, the jaw crusher is the most classic and secure choice for coarse crushing operations.