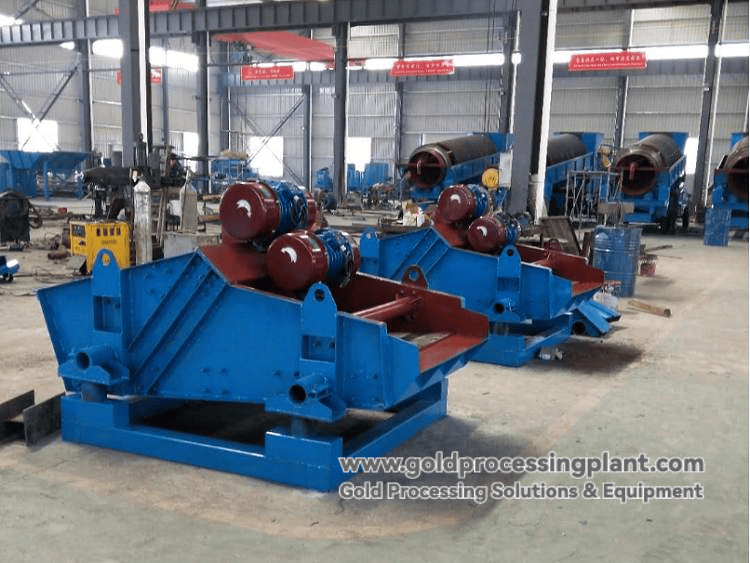

Product Overview

Dewatering sieve is a high-efficiency screening equipment specialized in material dewatering, desliming and demeshing. It adopts mature dual motor self-synchronous vibration technology, with large handling capacity, good dewatering effect, stable operation, easy maintenance and other outstanding features, widely used in sand and gravel plant washing sand, coal slurry recovery in coal processing plant, tailings dry discharge in mineral processing plant and other key operations, it is the core equipment to realize resource recovery and environmentally friendly production.

Core structure and working principle

The equipment consists of screen box, vibration motor, rubber spring support system and screen mesh. Two vibration motors make self-synchronous reverse rotation, generating strong directional excitation force, forcing the material on the screen surface to vibrate and move forward with high frequency. In this process, the water and fine mud particles are rapidly separated through the screen holes under the action of gravity and vibration force, while the dewatered coarse particles are discharged from the end of the screen surface, thus realizing efficient dewatering and grading.

Technical Advantages and Features

-

Highly efficient dewatering design:

-

The screen plate adopts a unique 5° front and 45° rear inclination arrangement, with pre-dewatering in the front section and forced dewatering in the rear section, resulting in extremely high dewatering efficiency.

-

The screen hole specification can be flexibly selected according to the material characteristics (e.g. particle size, viscosity) to achieve the best dewatering effect.

-

Smooth and reliable operation:

-

Dual motor self-synchronization technology, no need for gear forced synchronization, smooth running, low noise.

-

Adopting high-quality rubber spring damping, effectively absorbing the vibration of the equipment, small impact on the foundation, installation without complex foundation.

-

Sturdy and durable structure:

-

The screen box is made of thickened steel plate, the side plate is equipped with reinforcing rib structure, the overall rigidity is strong, and can withstand large loads of vibration.

-

Polyurethane or stainless steel screen plate is optional, wear-resistant, corrosion-resistant, long service life.

-

Strict welding process and quality control to ensure long-term reliable operation of the equipment.

Technical Parameter Table

| Model |

Screen size (W×L m) |

Motor power (kW×2) |

Processing capacity (m³/h) |

Equipment weight (kg) |

| TS0720 |

0.7 × 2.0 |

0.75 × 2 |

5 - 10 |

800 |

| TS0920 |

0.9 × 2.0 |

1.1 × 2 |

10 - 20 |

1200 |

| TS1020 |

1.0 × 2.0 |

1.5 × 2 |

10 - 30 |

1600 |

| TS1225 |

1.2 × 2.5 |

2.2 × 2 |

50 - 80 |

2100 |

| TS1530 |

1.5 × 3.0 |

3.0 × 2 |

100 - 120 |

3200 |

Note: The above capacity is a reference value for conventional materials, depending on the nature of the material, concentration and screen configuration.

Typical application areas

-

Sand and gravel aggregate industry: final dewatering operation of mechanism sand and washed sand, effectively controlling the water content of finished sand.

-

Coal processing field: recovering fine coal particles from coal slurry water, realizing closed-circuit recycling and resource utilization of coal slurry water.

-

Ore dressing production line: tailings dewatering and dry discharge, realizing tailings resource utilization or safe storage, reducing environmental pollution.

-

Other fields: Dewatering, desliming and demeshing of quartz sand, quartz sand, metallurgical slag and other materials.

Suggestions for model selection

-

According to the processing capacity: choose the appropriate model according to the hourly processing capacity demand, it is recommended to leave 10%-20% of the spare capacity.

-

According to the material characteristics:

-

Abrasive materials (such as slag, iron ore) is recommended to use polyurethane screen plate.

-

Stainless steel screen plate can be used in corrosive environment or high cleanliness requirement.

-

Special working conditions: according to the user's needs to customize the screen hole size, screen plate inclination or material, in order to perfectly adapt to the specific process.

Quality and Service Guarantee

-

Strict testing: each unit of equipment has passed strict no-load and load tests before leaving the factory to ensure that its performance is up to standard.

-

Reliable Warranty: Key equipment components (e.g. screen boxes, vibration motors) are covered by a 12-month warranty.

-

Technical support: provide a full range of professional technical support from site planning, installation guidance to commissioning optimization.

-

Customized service: support non-standard customization to meet the individual needs of special sites and materials.