Platinum Group Metals Beneficiation Process Overall Solution

I. Overview: Challenging the Limits of Beneficiation Technology

Platinum group metals (platinum, palladium, rhodium, ruthenium, iridium, osmium) are one of the rarest and most valuable metal groups in nature, and are the "vitamins" of modern industry, new energy, catalytic science and technology, and national defense. Due to its extremely low natural grade (often measured in grams per ton), wide variety of minerals, fine embedded particle size, and extremely complex symbiotic relationship, its beneficiation and recovery is known as the "crown jewel" in the field of mineral processing.

We specialize in solving the problem of extracting extremely complex and low-grade resources, and provide full-process, high-technology platinum group metal beneficiation solutions from geological sample analysis to final concentrate production, and are committed to maximizing the value of the resources in your hands.

II. Applicable resource types

-

Primary ore: primary platinum ore, copper-nickel sulfide ore associated platinum group metals

-

Alluvial o res: alluvial platinum ores

-

Secondary resources: waste automobile catalysts and chemical catalysts containing platinum group metals.

III. Platinum group metals core technology process: the precise art of multi-technology synergy

Aiming at the extreme characteristics of platinum group metals, which are "dilute, fine and heterogeneous", we have designed a set of highly efficient and stable platinum group joint process by adopting the strategy of " advance enrichment, stage dissociation and synergistic recovery ".

The first stage: pretreatment and precise crushing

-

Multi-stage crushing: A two-stage or three-stage closed-circuit process consisting of "Jaw Crusher + Cone Crusher" is used to crush the ore to a size suitable for grinding (-15mm), in preparation for high-efficiency grinding.

-

Stage Grinding - Classification: Ball mill and hydrocyclone are used to form a closed-circuit system. By precisely controlling the grinding fineness, the monomer dissociation of platinum group metal minerals is gradually realized, effectively avoiding the metal loss caused by over-grinding sludging, which is the basis for the success of subsequent sorting.

Stage 2: Gravity pre-enrichment - the key to "early harvesting and high yield"

-

Process Principle: Utilizing the extremely high density of platinum group metal particles, a re-election operation is set up after the grinding circuit to recover the dissociated coarse-grained monomer platinum group metals in advance.

-

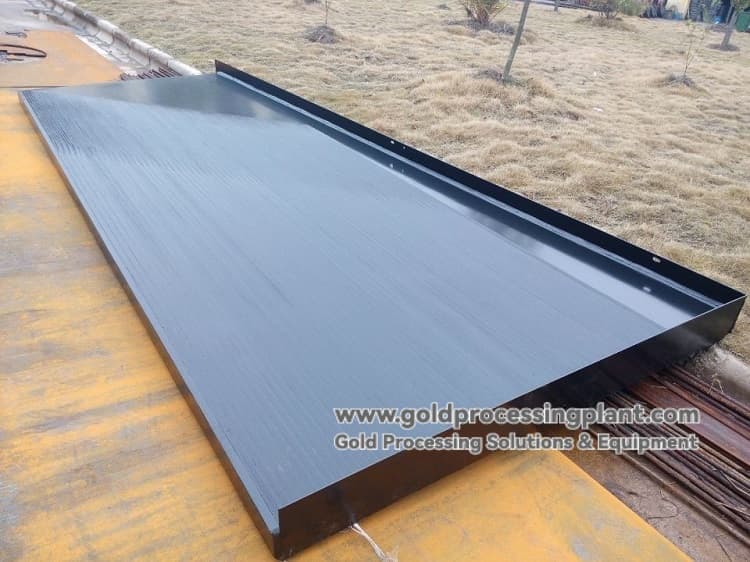

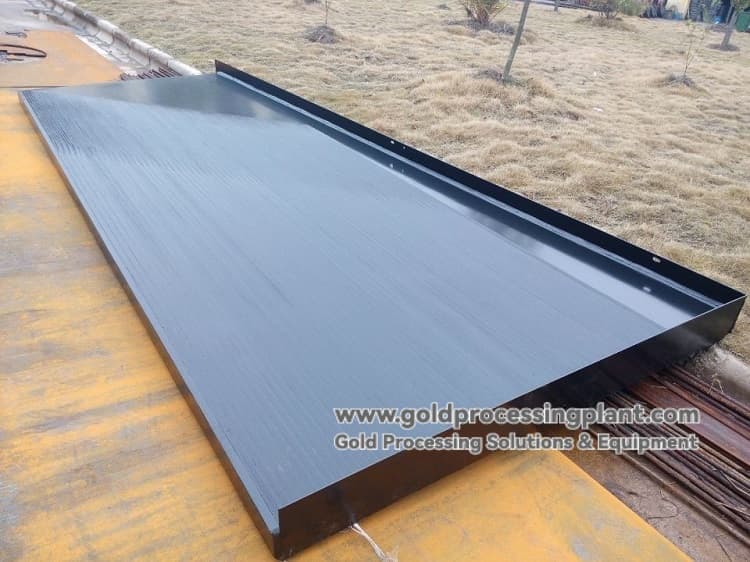

Core equipment: Centrifugal concentrators (e.g. Nelson concentrators), shaking tables.

-

Advantages:

-

Direct output of high-grade crude concentrate, significantly reducing the subsequent flotation processing load, saving energy and drug consumption.

-

Effectively prevents the crushing or loss of coarse-grained platinum group metals in the circulating load, contributing significantly to the overall recovery rate.

Stage 3: Flotation Enrichment - the heart and soul of the process

Flotation is the most effective means of recovering fine-grained embedded and sulfide-bound platinum group metals.

-

Proprietary Pharmaceutical System: Adopting our self-developed high-efficiency, highly selective recovery agents and combined inhibitors, which can be precisely adsorbed on the surface of the target minerals, greatly enhancing the separation efficiency of platinum-group minerals from veinstones and co-existing sulphides.

-

Stage grinding and flotation process: the scientific process of " coarse grinding and roughing - regrinding and selecting " is adopted. Roughing quickly throws off the tail, coarse concentrate regrinding to break the congenital body, and then through a number of selection to gradually improve the grade of the concentrate, and ultimately obtain high-quality platinum group metal concentrates.

-

Optimized equipment configuration:

-

Mechanical stirring flotation machine (for roughing and sweeping): large capacity and high recovery rate.

-

Flotation column (for concentrating): high sorting precision, large enrichment ratio, especially suitable for micro-fine-grained materials.

Phase IV: Concentrate treatment and deep purification

-

Magnetic separation: utilizing the magnetic difference of certain platinum group minerals (e.g. rhodium-iron alloy), separation by magnetic separator can further enhance the grade and value of final concentrate.

-

Concentration and dewatering: The flotation concentrate is dewatered by high-efficiency thickener and vacuum filter to get the filter cake with low moisture content, which is easy to transport or directly enter the smelting process.

Solution Core Advantages

-

Extremely high technology and recovery index:

-

The process is specially designed to overcome the platinum group metal beneficiation problems, and by virtue of the proprietary chemicals and joint flow, it realizes the efficient recovery of micro-fine grains and low-grade platinum group metals, and in particular, it can synergistically recover palladium, rhodium and other high-value rare metals.

-

Technological advancement and stability:

-

Excellent economic efficiency:

-

The highly efficient enrichment ratio of re-election and flotation greatly increases the concentrate grade and greatly reduces the subsequent smelting cost and transportation cost.

-

The high metal recovery rate directly translates into the core profitability of the project, significantly shortening the payback period.

-

Green and Sustainable:

-

Follow the principle of clean production and prioritize the use of environmentally friendly flotation chemicals.

-

Provide process water recycling system and exhaust gas collection and treatment solutions to minimize the impact on the environment, in line with the world's most stringent environmental standards.

V. Successful Cases: From Impossible to Possible

An ultra-low-grade co-production platinum and palladium ore project

-

Challenge: extremely low grade raw ore, fine embedded platinum and palladium minerals, close symbiosis with a variety of sulfides, and low economic value of the traditional single flotation process.

-

Our solution: We customized a combined process of " stage grinding - centrifugal re-election pre-enrichment - high-efficiency flotation (proprietary chemicals) - magnetic separation and selection ".

-

Results:

-

Successfully achieved a leapfrog improvement in platinum and palladium recovery, and economically recovered rhodium.

-

The deposit was transformed from a "potential resource" to an "economically recoverable reserve", and the economic benefits of the project were highly evaluated by the client's board of directors.

-

The success of this project has become a benchmark in the industry for handling similar complex resources.

Our Service Commitment: Expert Companionship Throughout the Process

We understand the complexity and high value of platinum group metals projects. We are not just an equipment supplier, we are your technical partner.

-

Mineralogical studies and selectivity tests: We provide detailed process mineralogical analyses and continuous laboratory/semi-industrial tests to provide you with a reliable basis for decision-making.

-

Customized engineering design and planning: Based on the test results, we can design the optimal process flow, plant layout and drawings for you.

-

Mineral processing equipment supply: We provide complete sets of platinum group metal processing equipment.

-

Expert project construction support: send a team of experienced engineers to provide on-site guidance on installation, commissioning and trial production to ensure that the project reaches production smoothly.

-

Personnel Training and Continuous Optimization: Train a comprehensive technical team for customers and provide long term production optimization and technical support services.

Contact us today for platinum group metals beneficiation process solutions and quotes, and start your journey to maximize the value of your platinum group metals project!