Need a plan quote or proposal? Available for free 24/7!

Contact: +8619914754015 (WeChat/WhatsApp)

Submit your inquiry for a tailored solution.

{{ variable.name }}

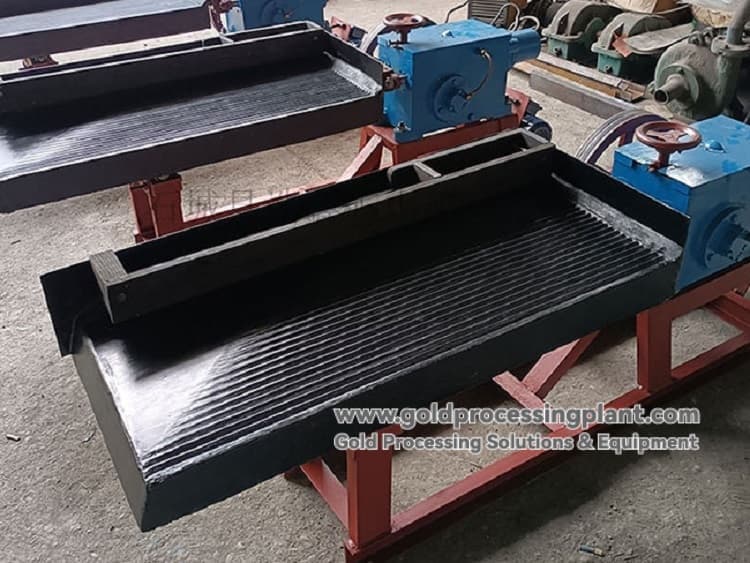

6-S Shaking Table is one of the core equipment of gravity separation, which is famous for its extremely high sorting precision and enrichment ratio. It uses a combination of physical forces (gravity, water impulse, bed friction and inertia) to precisely stratify and zone the ore particles according to their specific gravity and particle size, resulting in a one-time output of high-grade concentrate and waste tailings. The equipment is extremely widely used, applicable to tungsten, tin, tantalum, niobium, gold, silver, iron, manganese, chromium, titanium, coal and other metal and non-metallic minerals, and can be used for roughing, concentrating and sweeping and other kinds of operations, it is an indispensable precision sorting equipment for mineral processing plant.

The group of ore particles is fed from the feed chute of the inclined bed, and at the same time is subjected to the action of transverse flushing water. Under the combined effect of gravity, transverse water rushing force, inertia force and friction force generated by reciprocating asymmetric movement of the bed, the ore particles are stratified according to specific gravity and particle size.

Heavy mineral particles sink in the bottom layer, affected by the friction of the bed surface, along the longitudinal movement path.

Light mineral particles are located in the upper layer and are mainly washed by the transverse water flow.

Eventually, mineral particles with different specific gravity and particle size are fan-shaped from A side to B side of the bed, and are discharged from the concentrate end, the middle ore area and the tailing side respectively, and are precisely separated into concentrate, middle ore and tailing.

Extremely high sorting precision: high enrichment ratio (concentrate grade/feed grade), obtaining final concentrate and final tailings at one time, outstanding sorting efficiency.

Flexible operation adjustment: Stroke, number of strokes, lateral slope and flushing water volume can be easily adjusted to meet the needs of different minerals.

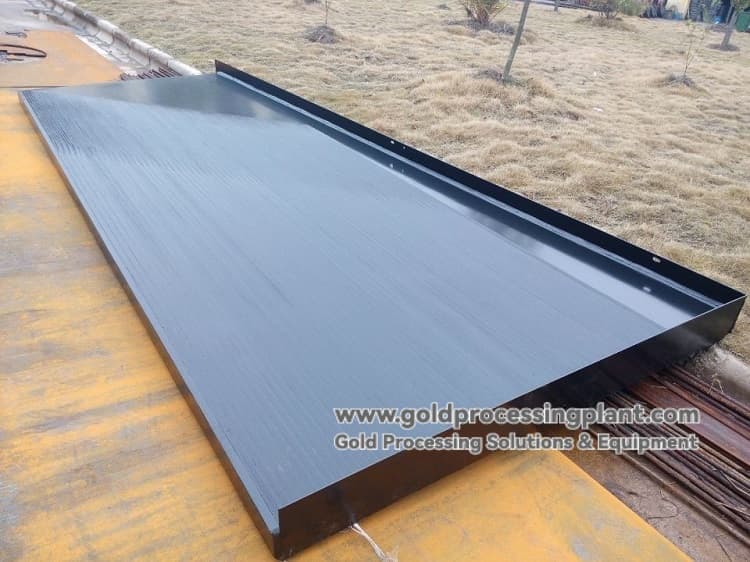

A variety of bed surface options: three different bed surfaces (grooved section) are available for coarse sand, fine sand and slime, and lightweight and wear-resistant materials such as glass fiber reinforced plastic can be selected to meet the sorting requirements of materials of different grain sizes.

Stable and reliable operation: The compact design with the spring placed in the box ensures smooth operation and maintains balance when adjusting the stroke. Sturdy structure, long service life.

Easy to care and maintain: simple operation, easy maintenance, low failure rate.

Applicable minerals: tungsten, tin, tantalum, niobium, gold, silver, iron, manganese, chromium, titanium, bismuth, lead, zinc and coal, etc.

Effective particle size range:

Coarse sand: 2 - 0.5mm

Fine sand: 0.5 - 0.074mm

Mud: < 0.074mm

*When processing tungsten and tin, the effective recovery particle size range is 2 - 0.022mm.

| Model and Parameters | 6-S 7.6 | 6-S 4.08 | 6-S 1.95 | 6-S 0.5 |

|---|---|---|---|---|

| Bed type | Coarse sand/fine sand/mineral mud | Three options available | Three options | Three options available |

| Bed Area (m²) | 7.6 | 4.08 | 1.95 | 0.5 |

| Feed size (mm) | Coarse sand: <2 Fine sand: <0.5 Sludge: <0.074 |

<2 (Sand) <0.074 (Mud) |

<2 (Sand) <0.074 (Mud) |

<2 (Sand) <0.1 (Mud) |

| Capacity (t/h) | Coarse sand: 1-1.2 Fine sand: 0.5-1 Mud: 0.3-0.5 |

0.4-1.5 | 0.3-0.8 | 0.05-0.2 |

| Stroke (mm) | 16-22 / 11-16 / 8-16 | 6-30 | 12-28 | 9-17 |

| Stroke (r/min) | 220 / 250 / 280 | 210-320 | 250-450 | 280-460 |

| Water consumption (t/h) | 0.7-1 / 0.4-0.7 | 0.3-1.5 | 0.2-1 | 0.1-0.5 |

| Motor power (Kw) | 1.1 | 1.1 | 1.1 | 0.55 |

Note: According to the different feeding position, each model can provide two configurations of left shaking table and right shaking table, which is convenient for the process layout of mineral processing plant.

Classic and Reliable: Proven classic design, one of the most popular shaker models worldwide.

Accurate and efficient: Unrivaled sorting accuracy is the ultimate guarantee of a high grade concentrate.

Flexibility and versatility: A wide range of sizes and bed types are available to meet the needs of the entire process from roughing to concentrating and from alluvial to slurry.

Economical and durable: Low energy consumption, low water consumption, robust equipment, low maintenance costs, high return on investment.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.