Need a plan quote or proposal? Available for free 24/7!

Contact: +8619914754015 (WeChat/WhatsApp)

Submit your inquiry for a tailored solution.

{{ variable.name }}

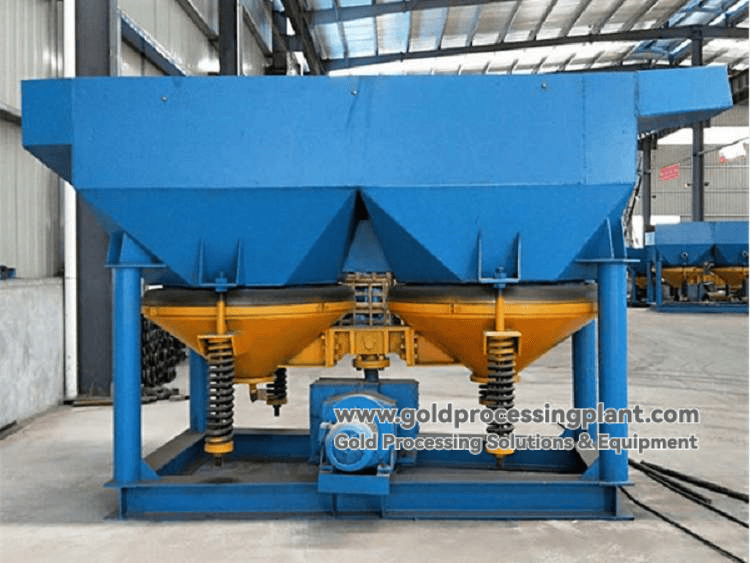

Sawtooth wave jigger is one of the core equipment in the field of modern gravity beneficiation. It breaks through the technical limitations of traditional jigger and realizes high sorting efficiency and high recovery rate through the innovative sawtooth pulsation curve. With large processing capacity and wide range of sorting particle size, this equipment is especially suitable for the sorting of non-ferrous, ferrous and non-metallic minerals, especially in the sorting of manganese ore, barite, iron ore and other minerals with excellent performance, and it is an ideal upgrading and replacement of the traditional jigger.

Defects of traditional jigger: The traditional equipment adopts circular eccentric drive, which generates sinusoidal pulsation curve, and its rising and falling water velocity and action time are basically the same, which is not conducive to the effective loosening of the bed and the stratification of minerals according to the specific gravity, and restricts the sorting indexes.

Technical breakthrough of sawtooth wave: This equipment is designed according to the theoretical stratification law of jigging bed, and produces sawtooth pulsation curve, which realizes:

Fast rising water flow and short time: rapid impact makes the bed layer loose quickly.

Slow descending water flow and long time: create sufficient stratification conditions, relieve the inhalation effect, and allow heavy mineral particles to fully settle.

Advantages: This asymmetric pulsation pattern greatly enhances the sorting effect, increasing Sn recovery by 3.01% and W by 5.5% compared with sine wave jigger, while reducing water consumption by 30%-40%.

High sorting efficiency: Sawtooth wave pulsation curve optimizes bed loosening and stratification, bringing higher enrichment ratio and recovery rate.

Powerful processing capacity: the equipment has a large processing capacity and a wide range of feed size (up to 30mm).

Significant energy saving and environmental protection: the amount of water replenishment under the screen is reduced by 30%-40% compared with the traditional equipment, with low energy consumption and a smaller footprint.

Flexible operation and adjustment: the stroke can be easily adjusted, driven by electromagnetic speed-regulating motor, stepless adjustment of stroke can be realized to adapt to different ore properties.

Simple and reliable maintenance: reasonable structure design, stable operation, easy installation, operation and maintenance.

Wide range of applications: suitable for alluvial gold, tin, tungsten, lead, zinc, iron, manganese, barite, coal and other minerals.

Metal ores: tin ore, tungsten ore, lead and zinc ore, alluvial gold ore, iron ore, manganese ore and so on.

Non-metallic ores: barite, fluorite, coal, etc.

Rare metals: ilmenite, diamond, etc.

Environmental Recovery: Recovery of valuable components from waste slag and tailings.

| Model | Jigging chamber shape | Area (m²) | Feeding granularity (mm) | Processing capacity (t/h) | Power (Kw) | Supplementary water quantity (m³/t) | Equipment weight (Kg) |

|---|---|---|---|---|---|---|---|

| JT0.57-1 | Trapezoidal | 0.57 | <12 | 1.5 - 3 | 1.5 | 1-2 | 610 |

| JT1-1 | Trapezoidal | 1.04 | <10 | 2.5 - 5 | 2.2 | 2-3 | 900 |

| JT2-2 | Rectangular | 2.28 | <10 | 5 - 10 | 3 | 2-4 | 1640 |

| JT3-1 | Trapezoidal | 3 | <10 | 7.5 - 15 | 5.5 | 3-6 | 3085 |

| JT4-2 | Rectangular | 4 | <25 | 8 - 20 | 7.5 | 4-8 | 3098 |

| JT4-2S | Rectangular | 4 | <25 | 8 - 20 | 4×2 | 4-8 | 3500 |

| JT5-2 | Trapezoidal | 4.86 | <10 | 12 - 25 | 7.5 | 3-6 | 4500 |

Note: The above are the parameters of some models, and the stroke and stroke times are adjustable. More detailed technical program can be provided according to customer requirements.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.